-

Maintenance method of flange ball valve

Flange ball valve maintenance methodFlange ball valve classification is stainless steel pneumatic ball valve, stainless steel electric ball valve, stainless steel manual ball valve. Flanged ball valves are very easy to contact with other metal and iron products during the manufacturing process. Regarding the situation that the flanged ball valve has not rusted, then everyone knows what maintenance work needs to be done for the flanged ball valve? The maintenance method of flange ball valve is as follows:1. After the finished product, after pickling, it must be rinsed. If there are sand holes or perforations, it should be gas shielded welding by argon arc welding. Then it is polished, and then solid-solution treatment is carried out;2. The finished product, after the pressure test is completed. It should be rinsed with water added with anti-rust powder.3. After installing the pipeline, regularly maintain and maintain it. For example, the valve stem is often lubricated. Properly open and…

-

Where should the check valve be installed?

Where should the check valve be installed? Did you pretend it right?Today we will discuss the installation location of the check valve. So how to determine the installation position of the check valve? What is the difference between the installation of the check valve before the pump and the installation of the check valve after the pump, and where does the installation before the pump apply? Check valves are usually used in conjunction with other valves. When used in conjunction with other valves, where should the check valves be installed? Let’s discuss it together.Check valve, also called check valve, is an automatic valve. It relies on the pressure of the flowing medium in the pipeline to push the disc to close and open the valve. When the medium stops flowing, the check valve disc closes, it can be effective Prevent the medium in the pipeline from flowing back, which plays a great role in ensuring…

-

Price of marine hydraulic butterfly valve with feedback

The principle of the balance valve is the anti-regulation in the valve body. When the pressure at the inlet increases, the diameter is automatically reduced to reduce the change of flow, and vice versa. If the connection is reversed, this adjustment system will not work. Moreover, the regulating valve is directional, and the reverse pressure can even reduce or even close the flow. Since the balance valve is installed for better heating, there is no problem of reverse installation. If it is a reverse installation, it is a human error, and of course it will be corrected. Balance valve belongs to the category of regulating valve. Its working principle is to change the flow resistance of fluid flowing through the valve by changing the gap between the valve core and the valve seat (that is, the opening) to achieve the purpose of adjusting the flow rate. The balance valve is equivalent to a throttling element whose…

-

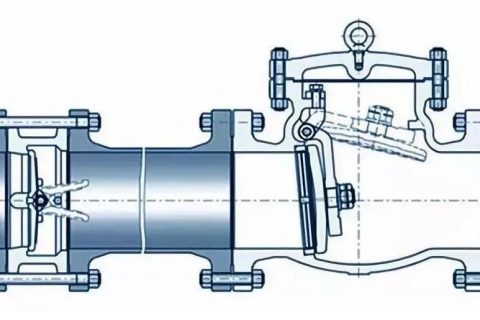

What is a marine valve

Marine valves are equipment that controls the pressure, flow and flow direction of the fluid in the ship’s pipes in order to meet the environmental conditions of the ship. A valve is a control device for a fluid pipeline. The basic function is to open or block the flow of the pipeline medium, change the flow direction of the medium, adjust the pressure and flow of the medium, and protect the normal operation of the pipeline equipment. Overview of Marine Valve Technology Development Since the birth of the People’s Republic of China, my country’s marine valve technology has achieved rapid development. Through the transfer of early Soviet products, major auxiliary sintering, serialization and standardization, and self-research and design, it has basically met the needs of my country’s shipbuilding industry. A total of 12 universal valves have been designed. Category, 1400 specifications. The maximum pressure of the valve is 25MPa, and the maximum diameter…

-

Marine pressure reducing valve-DIN type branch pressure reducing valve

Product name: Marine DIN type branch pipe pressure reducing valve Shanghai quality marine valve produced marine valves according to China GB, Ministry of Machinery JB, chemical standard HG, American standard API, ANSI, German standard DIN, Japan JIS, JPI, British standard BS For production, the company actively implements the ISO9001: 2000 quality certification system, and strictly follows the technical standards and drawings for design, production and inspection. With excellent quality, perfect service and timely delivery, it has won the unanimous trust and praise of many shipbuilding and ship repairing companies. And according to user needs, we can provide product inspection certificates of CCS, LR, ABS, GL, DNV, BV, NK, RINA and other world-renowned classification societies. The quality-bearing valve has professional production equipment and technical engineers, and has the ability to manufacture high-quality marine valves in accordance with national standards and various industry standards. Disclaimer:All text, data, and pictures in this article are for reference…