-

A Breakdown of Industrial Valve Types

A Breakdown of Industrial Valve Types Valves are arguably the workhorse of piping systems. There are many different types of industrial valves that perform countless jobs from isolating to regulating flow in a variety of different industries, from ball and globe valves used in the power industry to butterfly valves in pharmaceutical processing to gate valves in oil and gas production. While valves all play similar roles, it’s in their differences that they shine – ball valves help regulate flow, check valves prevent backflow, and gate valves are ideal for high temperatures and pressures. Today we’ll take a closer look at a few of the most common types of valves: ball, butterfly, check, gate, and globe valves. What are Ball Valves? Ball valves are a compact, cost-efficient, and low maintenance quarter-turn valve. Inside the valve is a ball with a hole in it. When this valve is open, the hole…

-

Global Industrial Valves Market to Reach $92.3 Billion by 2026

Global Industrial Valves Market to Reach $92.3 Billion by 2026 Industrial valves are mechanical or electromechanical devices intended to control, divert and regulate pressure and flow of fluids by opening, blocking or closing fluid passage. Industrial valves are mainly utilized in capital-intensive industries, as these industries require a large number of valves during the installation stage. The valves are also utilized as flow controllers for pipelines, through which gases, liquids and semi-solids are transported. Amid the COVID-19 crisis, the global market for Industrial Valves estimated at US$73.2 Billion in the year 2020, is projected to reach a revised size of US$92.3 Billion by 2026, growing at a CAGR of 3.9% over the analysis period. Ball Valves, one of the segments analyzed in the report, is projected to grow at a 4.1% CAGR to reach US$30.6 Billion by the end of the analysis period. After a thorough analysis of the business…

-

Mogas Industries acquires Watson Valve assets

Mogas Industries recently completed the asset acquisition of Watson Valve, a Houston-based turnkey manufacturer of heavy-duty service valves, including repair and coating services. Watson has more than 3,400 valve installation bases worldwide, mainly used in the mining industry, but also in the oil, gas and chemical industries. This strategic acquisition expands Mogas’s global mining operations in valve supply and valve repair services and adjacent market opportunities, especially those related to the autoclave market. It also provides opportunities for Mogas by incorporating long-term mining customers into its product portfolio, especially in North America. Mogas is committed to leveraging its extensive global network of internal and authorized repair centers to provide comprehensive support and comprehensive services for the additional customer base brought about by this purchase. Matt Mogas, President and CEO of Mogas, said: “This acquisition allows Mogas to expand its product portfolio and move closer to realizing our vision as a leading critical…

-

Valve positioner installation instructions

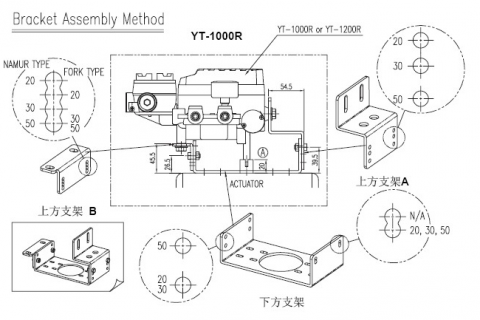

Valve positioner is an important accessory used in pneumatic valve to adjust flow. It is usually used with pneumatic actuator. It can control valve opening by receiving the signal of 4-20mA in controller or control system, so as to control the process parameters of pipeline medium accurately. Valve positioner is composed of pneumatic actuator, and then connected with various automatic control units or valves. After debugging and installation, it is combined into pneumatic regulating valve valve, which is used in various industrial automation process control fields. Valve positioner can be divided into pneumatic valve positioner, electrical valve positioner and intelligent valve positioner according to structure. [valve positioner installation process] 1. The height (H) of the shaft of the general pneumatic actuator can be divided into three types: 20, 30 and 50mm. After confirming the height of the actuator shaft, assemble the bracket according to the picture below. 2….

-

The development trend of automated valves

The rise of the industry has brought us many entrepreneurial and employment opportunities. For example, due to the sharp increase in labor costs, more and more customers have begun to choose pneumatic, electric and other automated valves. Most of them are supplied to the machinery manufacturing industry. The booming business of related machinery manufacturing has also increased sales for us. This phenomenon is like a vine. The growth of a vine benefits the whole vine. Those who are familiar with valves know this, an important advantage of automation is to liberate manual labor, improve production efficiency, and enable machinery and equipment to automatically operate or process control in accordance with pre-set procedures or commands without human intervention. , Its goal is “stable, accurate and fast.” In response to this information, the automated valve equipment launched on the market largely met the needs of the market, cleared the obstacles in the development…

-

Briefly talk about the development of several major valve markets

1. Energy Industry For a long time, the energy industry’s demand for valves has maintained a solid and stable growth rate. The total power generation of thermal and nuclear power plants built around the world is 2679030MW, the power generation of the United States is 743391MW, and the power generation of new power plants in other countries in the world is 780,000MW, which will increase by 40% in the next few years. Europe, South America, Asia, especially China’s energy market will become a new growth point for the valve market. 2. Chemical industry The chemical industry ranks first in the industry with an output value of more than 1.5 trillion US dollars, and it is also one of the largest demand markets for valves. The chemical industry mostly needs industrial valves with mature designs, high processing quality and rare materials. 3. Oil and gas industry In North America and some developed countries, there…

-

Working principle and advantages of high pressure and high temperature gate valve

The high-pressure and high-temperature gate valve is a common cut-off valve. Such a valve can directly cut off the medium in the pipeline, but it cannot be used for flow adjustment. This kind of valve has strong adaptability and can be used in various pressure and temperature environments. So what are the working principles and advantages of this type of valve? working principle The high pressure and high temperature gate valve of the upper pot valve adopts a compact structure. The pressure self-tightening structure can ensure a good application effect, and there are elastic splints inside, and the branch pipes on both sides can be directly used as welding connections, so that subsequent installations More convenient. The cobalt-based cemented carbide is used for spray welding on the valve seat sealing surface, so it can ensure good wear resistance and also ensure the sealing effect. In addition, the surface of the valve stem is also treated with corrosion…

-

To develop the industrial real economy, valve companies take the road of sustainable development with innovative technology

In the development of the national economy, industry is the top priority of the economy and the foundation of economic development. In this period of coexistence of opportunities and challenges, real industrial enterprises must put technology first if they want to take a broad road of sustainable development. Only by implementing technological innovation can it be in line with the market and provide new momentum for enterprise development. In the field of industrial valves, Shangguo Valve is an enterprise specializing in the development and production of various valves, such as power station valves, butterfly valves , regulating valves , and high temperature valves. Among them, there are different types of subdivisions in butterfly valves, and the classification method is mainly based on different functions and usage scenarios. For example, HD7X41X type PN6~PN16 accumulator hydraulic slow-closing check butterfly valve is mainly used on parallel units of thermal power plants or gas waste heat generating units. It can protect the…

-

Master the core technology of high-end valves, innovate and seek development, and let Chinese manufacturing go to the world

In recent years, looking at the valve industry, there are still many shortcomings and shortcomings in many high-end valve research and development fields, and mastering the core technology of high-end valves is of great significance for promoting the high-quality development of my country’s economy and enhancing the country’s comprehensive strength. How to improve the key core technological innovation capabilities of my country’s industrial products and firmly grasp the initiative of scientific and technological development in their own hands is a topic and challenge faced by every Canadian enterprise and every technical researcher. It is true that some companies have achieved success on the journey of innovative research and development. Shangguo Valve has its own complete set of systems in terms of technical research. The first is to increase the allocation of high-tech personnel, and more resources are tilted towards technology research and development; second, to learn advanced foreign technology, adhere to the strategy…